Turbo Compressor-Gas Compressor

- Full Description

Details about Turbo Compressor-Gas Compressor

In a world where efficiency and safety are paramount, the Gas Turbo Compressors developed by SmarTurbo represent an advanced solution designed to meet the highest requirements. These devices are ideally suited for handling a wide range of gases, including CH4, CO2, neon, argon, helium, krypton, xenon, and radon, while providing the highest level of explosion protection, class IIBT3. Whether operating in environments with heightened explosion risks involving hydrogen sulfide, ethylene glycol, hydrogen, oxygen, or biogas, SmarTurbo’s Turbocharged Gas Compressors ensure safety and reliability throughout their operation.

The design of SmarTurbo’s Gas Compressors incorporates a series of modern solutions that significantly reduce electricity costs (by up to 50%) and extend the service life under heavy and intensive loads.

Turbo Compressor Core Technology

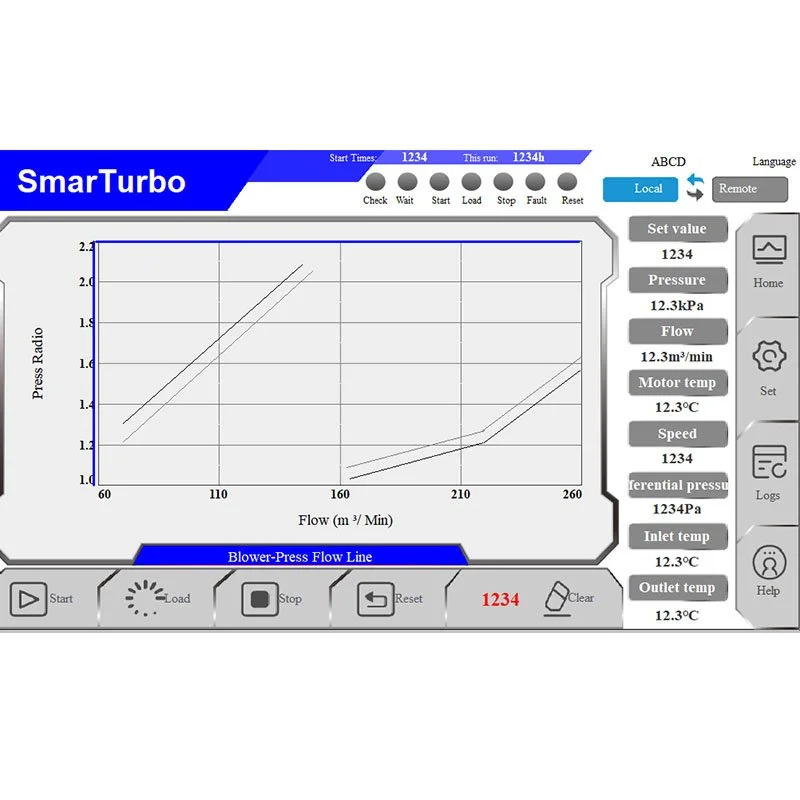

Turbo compressor consist of core technology of Turbo Compressor Engine, High Speed VFD, Smart Control System, Touch Screen Control Panel and Mobile Phone Remote Control.

High Speed VFD

The developed high performance VFD for high speed permanent magnet motor is more energy-saving and high-efficient.

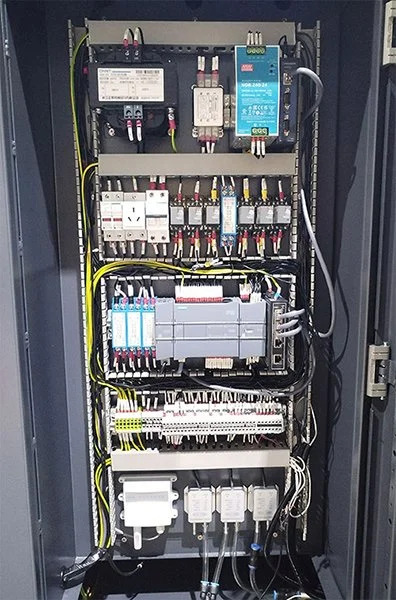

Smart Control System

It adopts PLC control with multiple communication method. Multiple control and monitoring is available, including the on-site, DCS remote and 4G-LTE.

Through state monitoring of logic data, built-in control program automatically detects, judges and terminates abnormal operation.

One-button start-stop control is reserved to facilitate on-site commissioning and troubleshooting under abnormal operation in time.

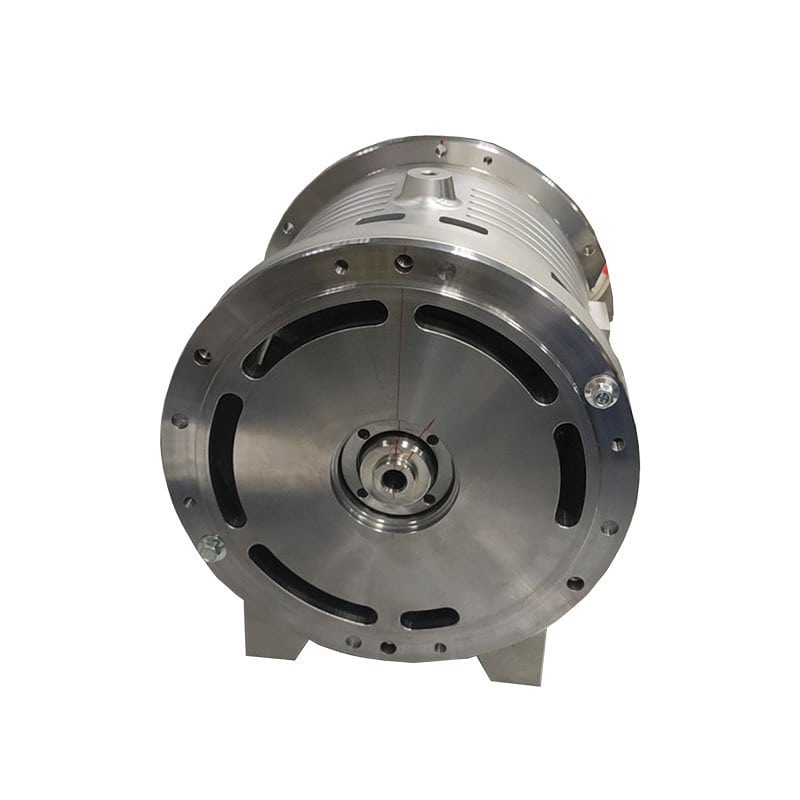

Turbo Compressor Engine Technology

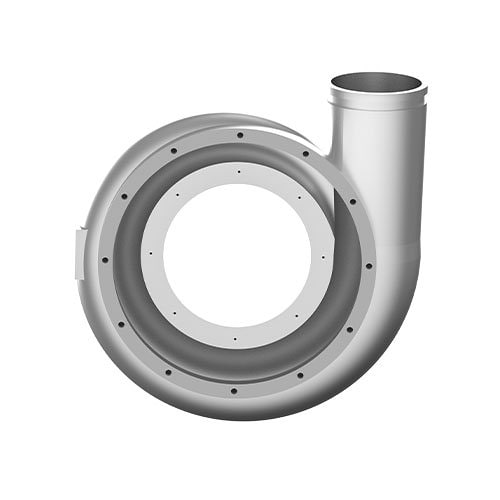

Turbo compressor engine consist of core technology of High Speed Impeller, High Speed Motor, Air Bearing, High Speed Rotor, High Speed Rotor Coil and Volute.

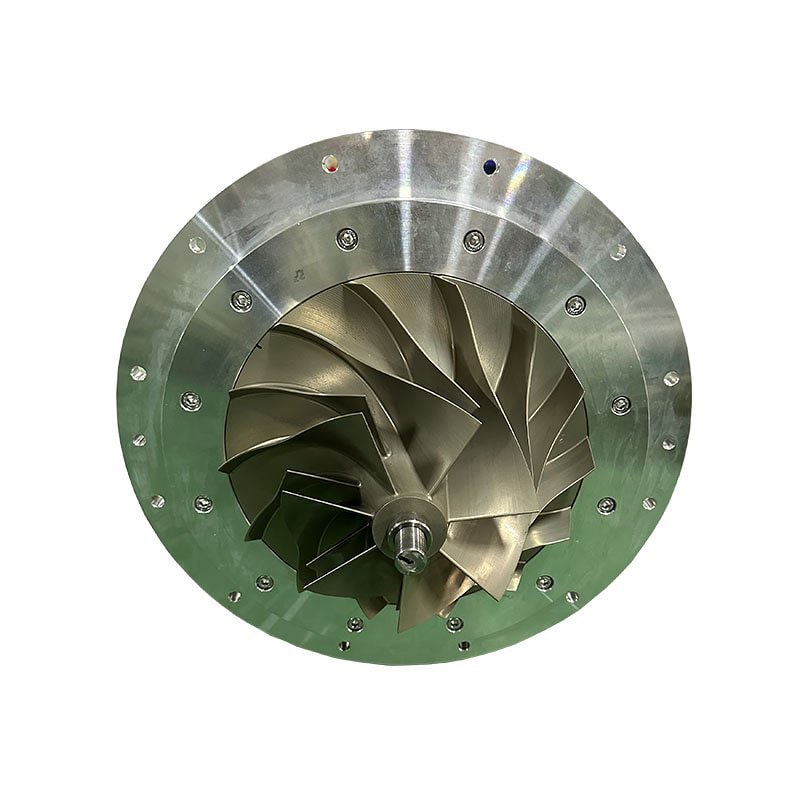

Anti-corrosive Coated Impeller

Turbo compressor gas compressor engine adopts high speed impeller with anti-corrosive coating, which is good for long-term service life of impeller and improves impeller efficiency.

High Speed Motor

Permanent magnet synchronous motor is with electromagnetic efficiency up to 98%, wide range of high efficient operation, directly-driven loading, and without transmission loss.

Air Bearing

Air bearing is designed for complex operating conditions like high speed, extreme temperature, large loading and strong vibration.

Airtight design

Turbo compressor gas compressor engine adopts professional sealed motor to avoid gas leakage.

- Benefits and Features

-

Turbo Compressor-Gas Compressor Advantage

-

High Efficiency Turbo blower saves 50% more electricity than traditional roots blower.

-

Smart Control Turbo blower adopts a touchscreen control panel and mobile phone remote control. It supports multiple control methods.

-

Plug and Play Turbo blower airflow and pressure are adjusted by blower rotation speed.

-

Easy Maintenance Regularly replace filter cotton as per the hints. The maintenance is easy and fast at an extremely low cost.

-

- Areas of use

-

Turbo Compressor-Gas Compressor areas of use

Gas Compressors are used in many industries, including:

-

Oil and Gas Industry: for gas transportation through pipelines, increasing pressure in wells to enhance extraction;

-

Chemical Industry: in numerous technological processes (compression of hydrogen and nitrogen in the production of ammonia, compression of ethylene, propylene, and other monomers for polymerization processes, among others;

-

Cement Production In cement plants, turbo equipment can be used to support aeration, mixing, and transport processes for powdered and granular components.

-

Fertilizer Production: utilized in various stages of nitrogen and phosphate fertilizers production;

-

Glass and Cement Manufacturing: in oxidative and reductive processes that require precise gas flow control.

They are also employed in electricity generation and wastewater treatment.

-

- Technology

-

Air Bearing

Air bearing is designed for complex operating conditions like high speed, extreme temperature, large loading and strong vibration.

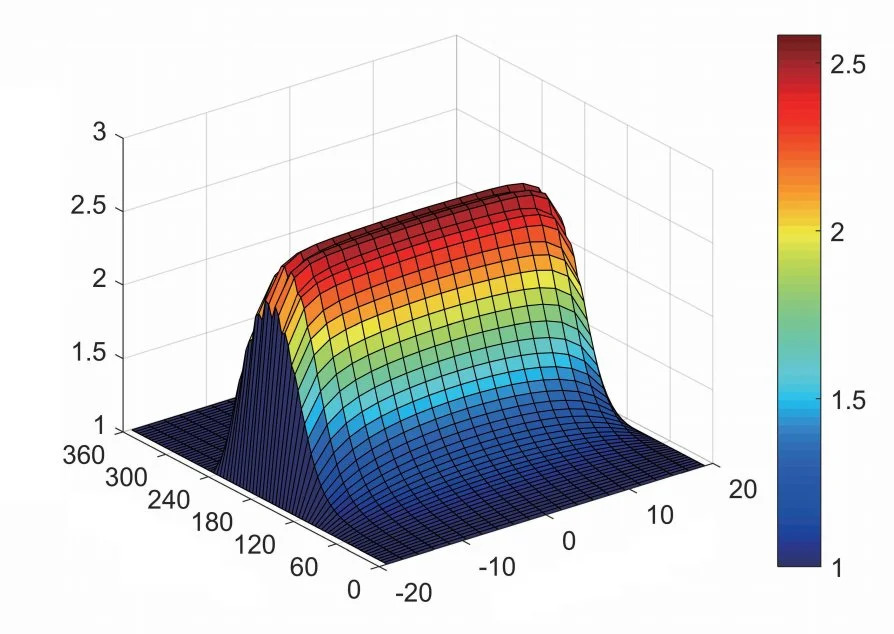

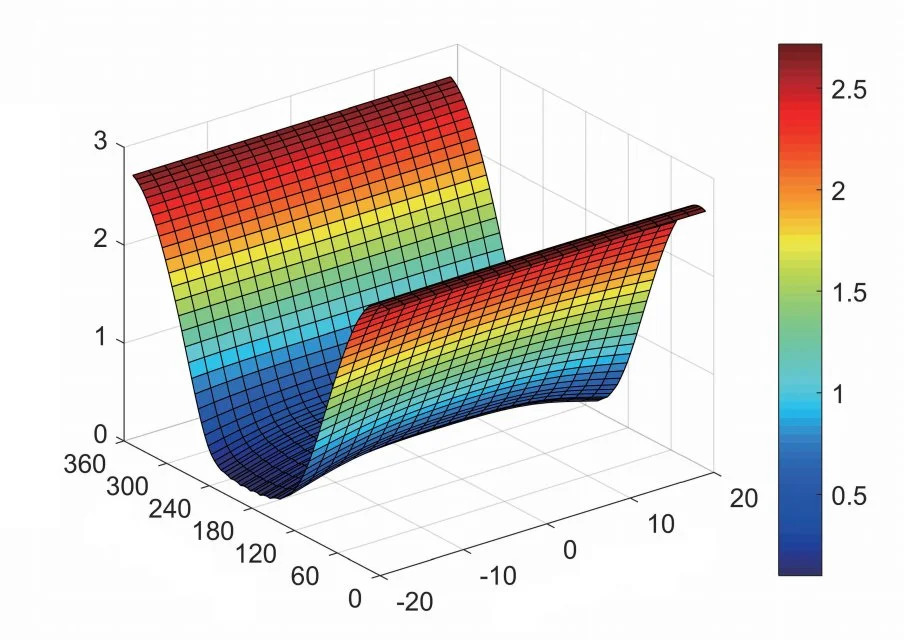

Design Simulation

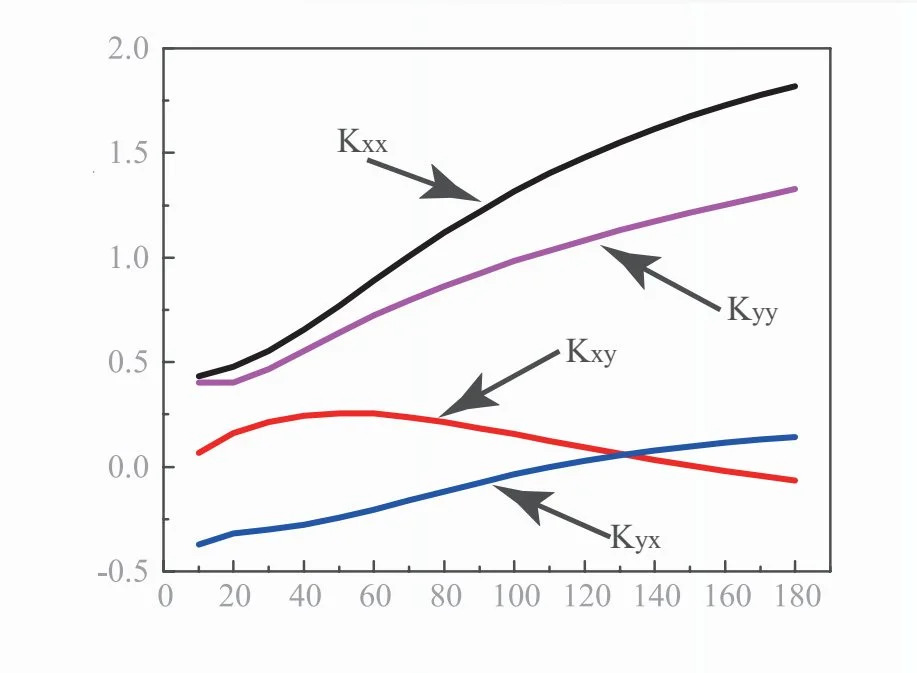

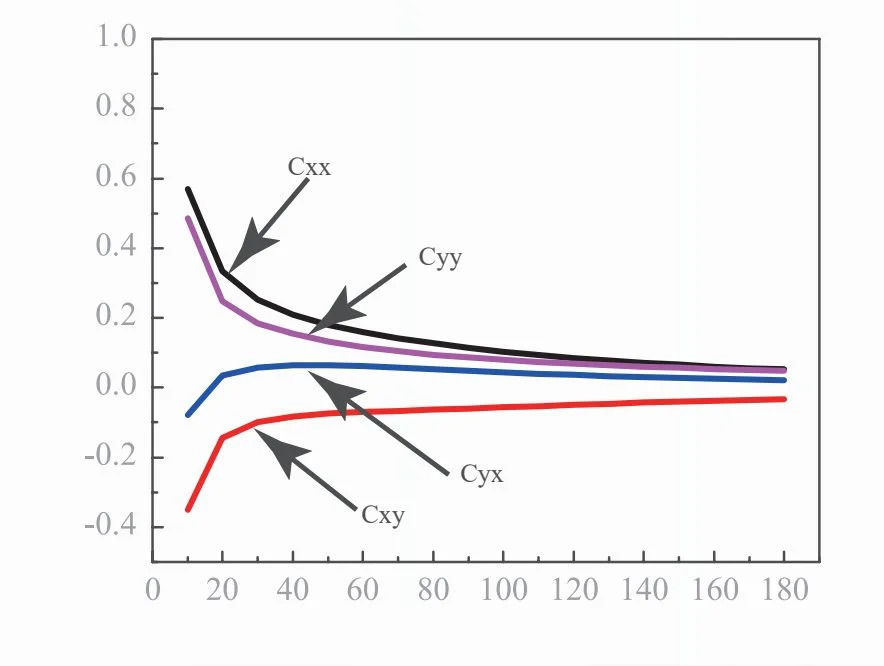

The bearing load capacity, rigidity and damping coefficients can be precisely predicted by the self-developed simulation software for air bearing performance.

A series of bearing development is completed: bearing diameter range of 20mm~100 mm; bearing operating speed ranges from 20 krpm to 200 krpm. The power of air bearing supported machine ranges from 10 kW to 500 kW.

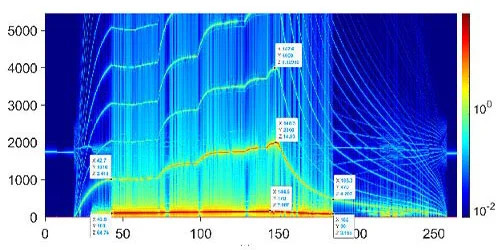

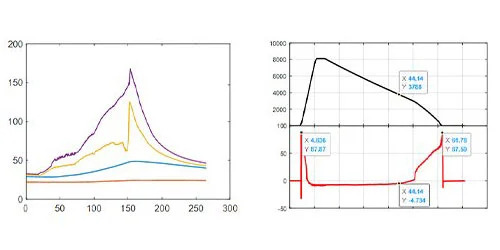

Test

A comprehensive air bearing test system has been established. Our fully-developed bearing test capability and data analysis capability can carry out performance verification for air bearing and provide technical support for the test, as a result tailor-made products can be realized.

Manufacture

By complete production process flow for air bearing and the perfect supply chain system, the key and core process manufacture can all be carried out by ourselves. With an annual output of 5000 sets of bearing, it realizes bearing series, batch production and supports bearing customization.

Specifications of the Turbo Compressor-Gas Compressor

Turbo Blower Parameter Table

| Model | 100HP | 125HP | 150HP | 200HP | 250HP | 300HP | 400HP | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Discharge Pressure, kpa | Air Flow (m³/min),20 ℃,Humidity 60%, 1atm | ||||||||||

| 150 | 32 | 48 | 60 | 69 | 121 | / | |||||

| 200 | 25 | / | 37 | 65 | 71 | 75 | 100 | ||||

| 300 | / | / | / | / | / | 105 | |||||

| 350 | 20 | / | / | 37 | / | / | / | ||||

| 400 | / | / | / | 36 | / | 55 | / | ||||

| 500 | / | / | / | / | / | 46 | 58 | ||||