Turbo Compressor-Magnetic Bearing Turbo Compressor

- Full Description

Details about Turbo Compressor-Magnetic Bearing Turbo Compressor

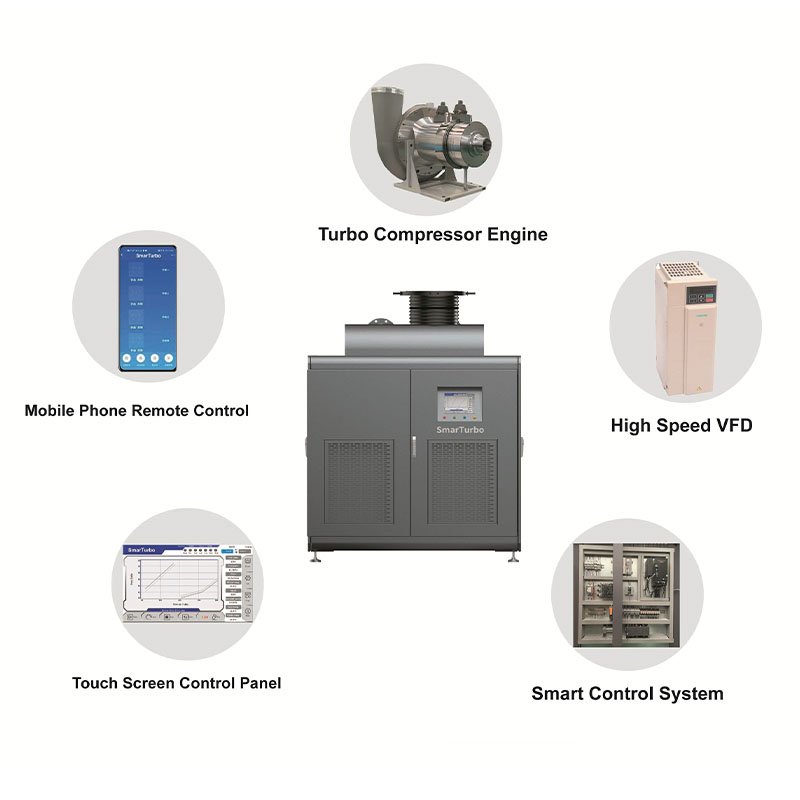

Leveraging cutting-edge developments and proprietary research in magnetic bearings, SmarTurbo offers a solution that ensures long-term investment appeal by reducing energy and maintenance costs. SmarTurbo's Turbo Compressor-Magnetic Bearing Turbo Compressors are equipped with a range of high-tech devices that collectively deliver high efficiency.

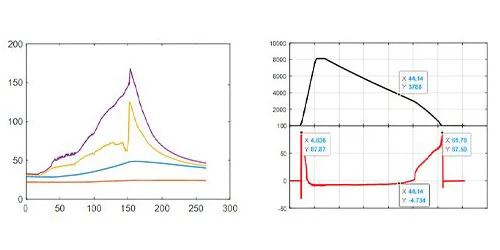

Turbo Compressor Core Technology

Turbo Compressor consist of core technology of Turbo Compressor Engine, High Speed VFD, Smart Control System, Touch Screen Control Panel and Mobile Phone Remote Control.

High Speed VFD

The developed high performance VFD for high speed permanent magnet motor is more energy-saving and high-efficient.

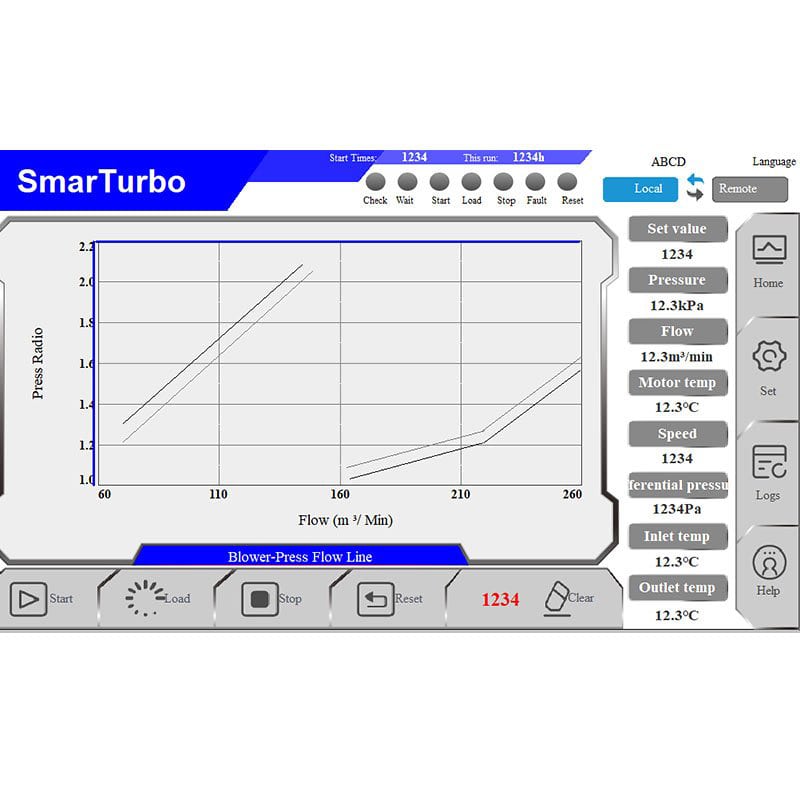

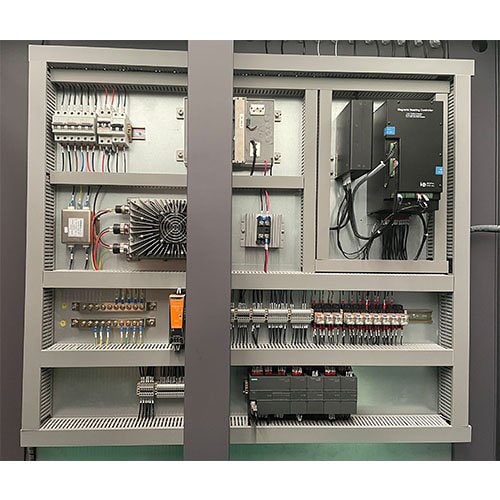

Smart Control System

It adopts PLC control with multiple communication method. Multiple control and monitoring is available, including the on-site, DCS remote and 4G-LTE.

Through state monitoring of logic data, built-in control program automatically detects, judges and terminates abnormal operation.

One-button start-stop control is reserved to facilitate on-site commissioning and troubleshooting under abnormal operation in time.

Turbo Compressor Engine Technology

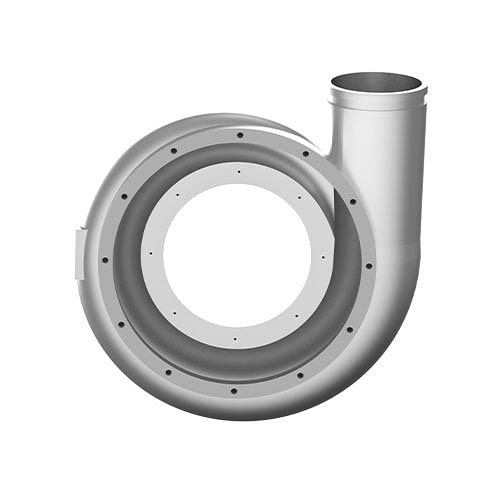

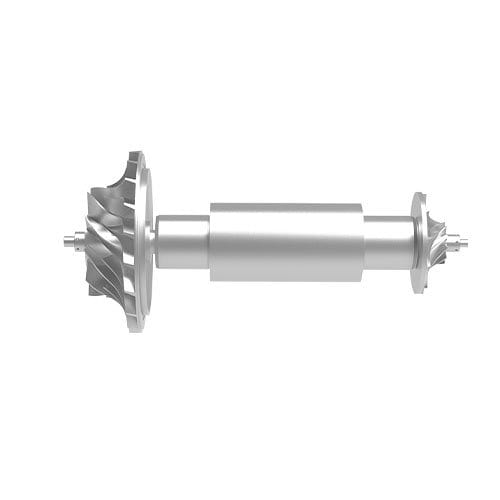

Turbo compressor engine consist of core technology of High Speed Impeller, High Speed Motor, Magnetic Bearing, High Speed Rotor, High Speed Rotor Coil and Volute.

High Speed Impeller

Turbo compressor engine adopts design concept of three-dimensional flow impeller, which improves impeller efficiency up to 95%,realizes wide operation range, and volume flow adjustable from 45% to 100%.

High Speed Motor

Permanent magnet synchronous motor is with electromagnetic efficiency up to 98%, wide range of high efficient operation, directly-driven loading, and without transmission loss.

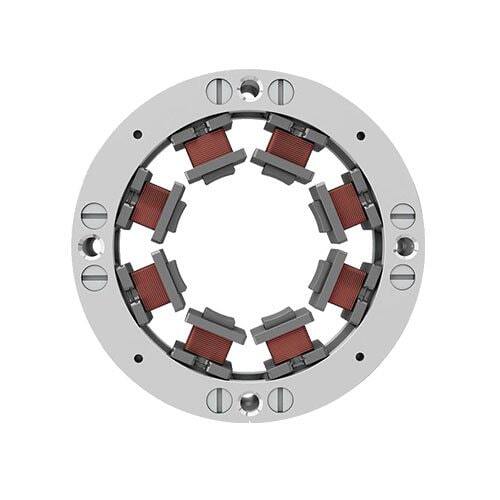

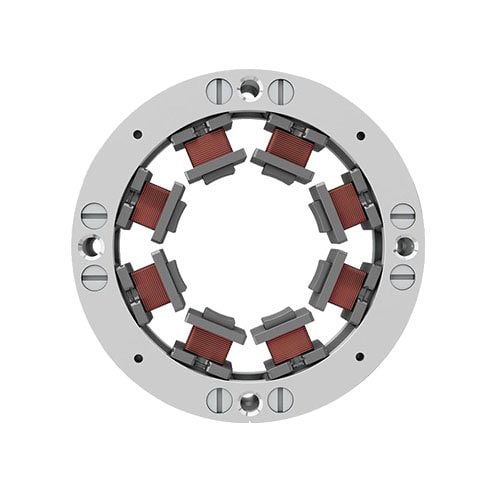

Magnetic Bearing

Air bearing is designed for complex operating conditions like high speed, extreme temperature, large loading and strong vibration.

High Speed Rotor

Variable frequency and speed control is good for the motor rotating in maximum speed of 200000 rpm.

- Benefits and Features

-

Turbo Compressor-Magnetic Bearing Turbo Compressor Advantage

-

High Efficiency Turbo blower saves 50% more electricity than traditional roots blower.

-

Smart Control Turbo blower adopts a touchscreen control panel and mobile phone remote control. It supports multiple control methods.

-

Plug and Play Turbo blower airflow and pressure are adjusted by blower rotation speed.

-

Easy Maintenance Regularly replace filter cotton as per the hints. The maintenance is easy and fast at an extremely low cost.

-

- Areas of use

-

Turbo Compressor-Magnetic Bearing Turbo Compressor areas of use

-

Chemical Industry Magnetic bearing turbo compressors are utilized for processes that require a continuous supply of compressed air or gas at high pressure, such as chemical reactions, transportation, or cleaning processes.

-

Oil and Gas Industry At oil refining and gas processing plants, turbo compressors are used to increase gas pressure in catalytic reforming, distillation, and other processes that require high pressure.

-

Energy Sector This equipment is used in thermal and nuclear power plants to support the operation of gas turbines, as well as in ventilation and air conditioning systems.

-

Wastewater Treatment In wastewater treatment facilities, magnetic-bearing turbo compressors are employed for aeration – saturating water with oxygen to support the biological cleaning process.

-

Semiconductor Manufacturing Turbo equipment is used to supply clean compressed air or special gases.

-

Food and Pharmaceutical Industry Magnetic bearing turbo compressors find application in drying processes, aeration, and pneumatic transportation of products.

-

- Technology

-

Magnetic Bearing

Magnetic bearing is designed for complex operating conditions like high speed, extreme temperature, large loading and strong vibration.

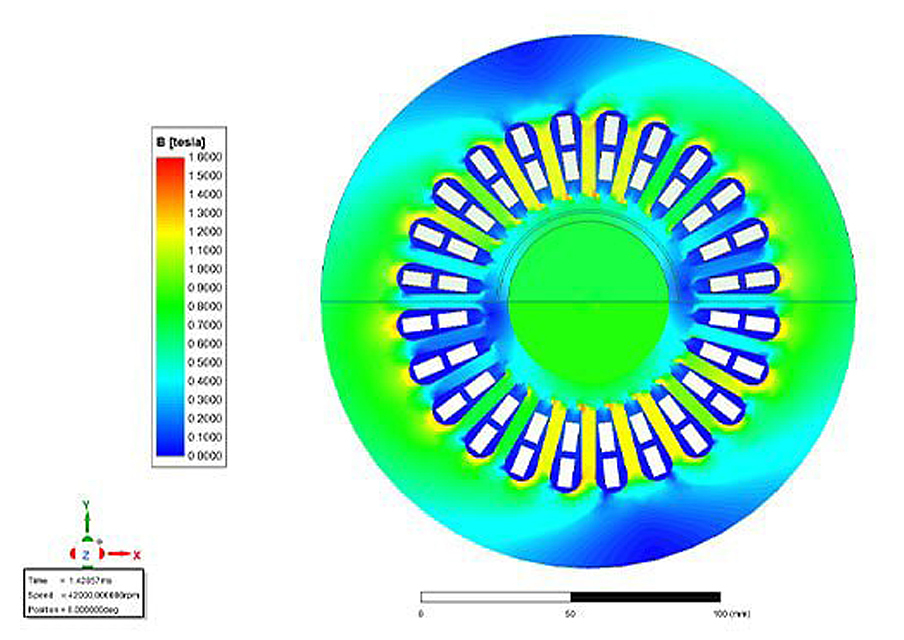

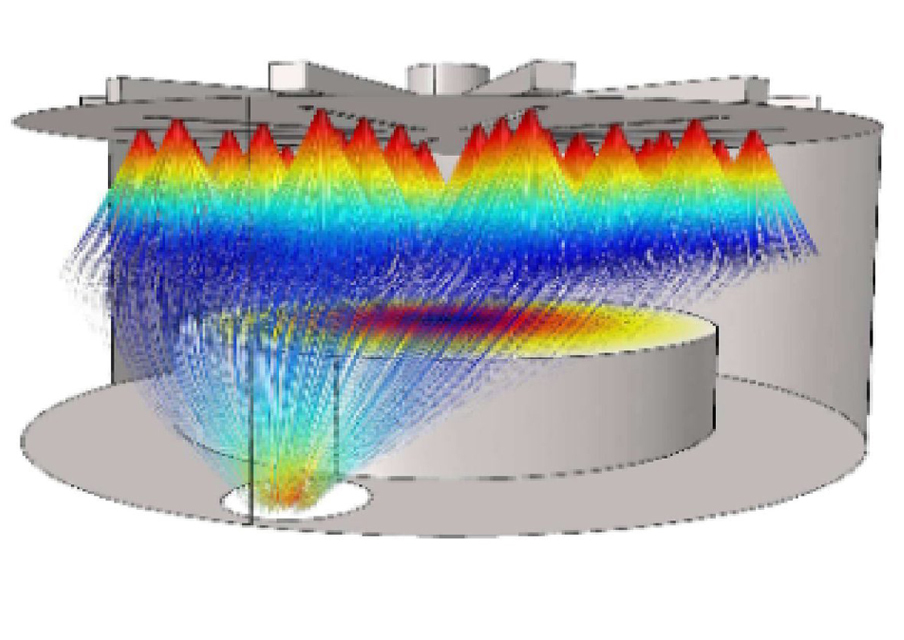

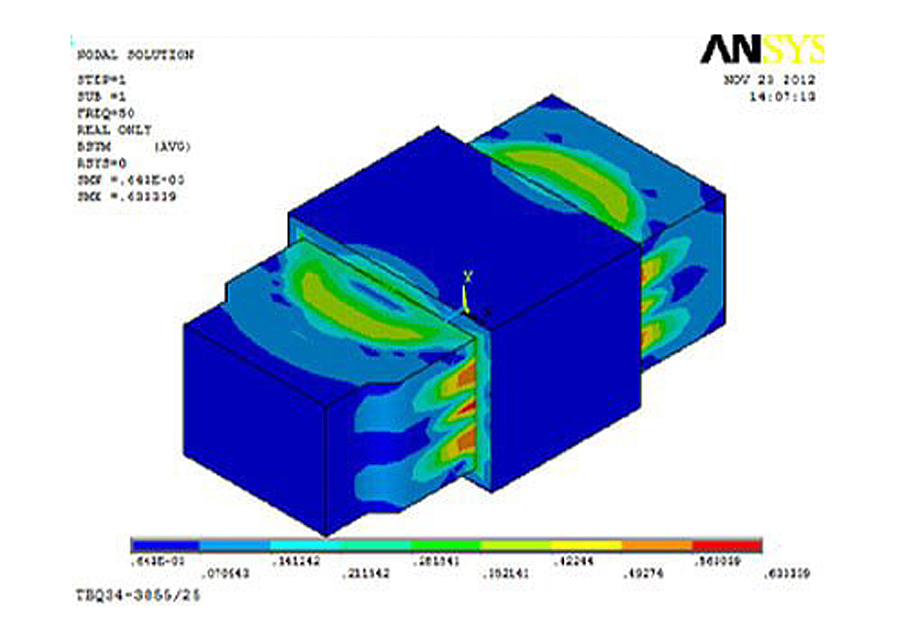

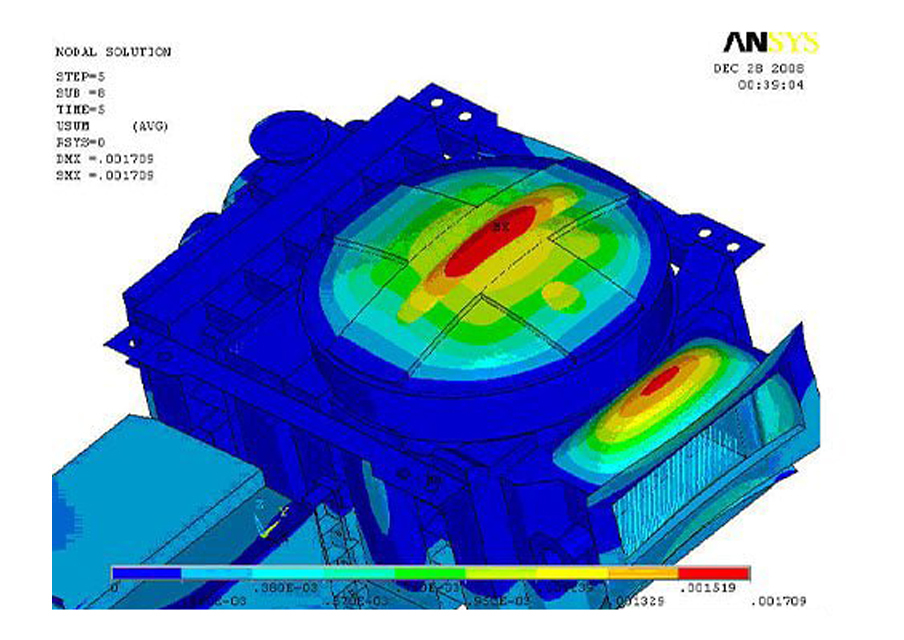

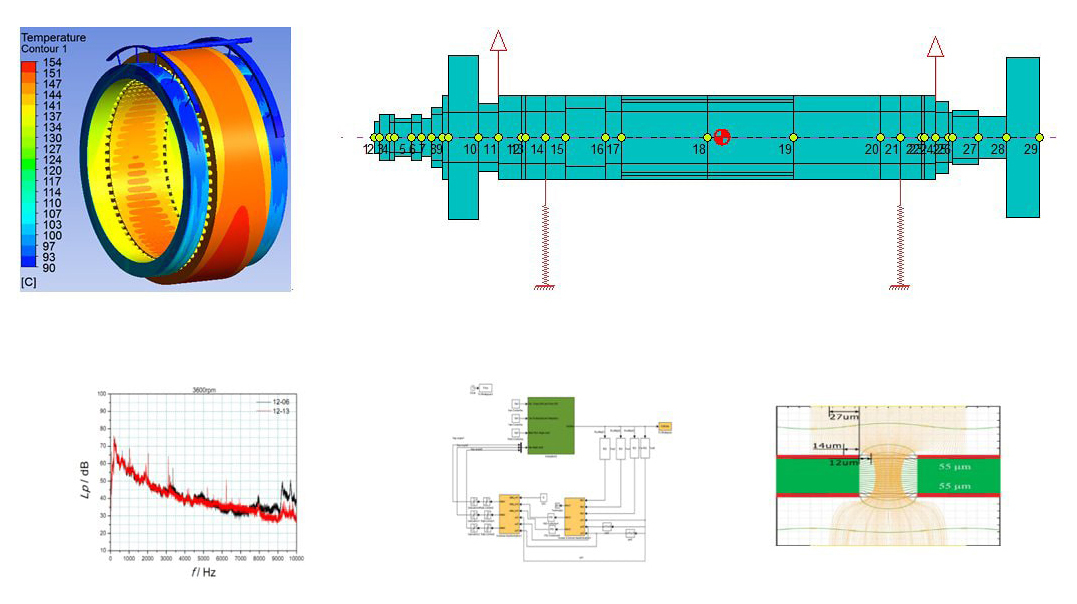

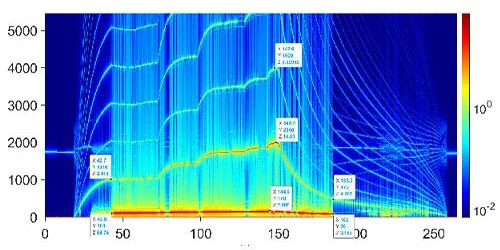

Design Simulation

To ensure the magnetic bearing performance, our self-developed simulation software do the follow simulation: magnetic field simulation, electric field simulation, multi-physics coupling simulation, mechanical stiffness and strength simulation, temperature simulation, vibration and noise simulation, rotor dynamics simulation, system simulation etc.

Test

A comprehensive air bearing test system has been established. Our fully-developed bearing test capability and data analysis capability can carry out performance verification for air bearing and provide technical support for the test, as a result tailor-made products can be realized.

Manufacture

By complete production process flow for air bearing and the perfect supply chain system, the key and core process manufacture can all be carried out by ourselves. With an annual output of 5000 sets of bearing, it realizes bearing series, batch production and supports bearing customization.

Specifications of the Turbo Compressor-Magnetic Bearing Turbo Compressor

Turbo Blower Parameter Table

| Model | Air Flow | Pressure | Power |

|---|---|---|---|

| // | m3/min | bar(G) | KW |

| 75KW-1.5 | 20-31 | 1.2-1.5 | 75 |

| 110KW-2 | 27-49 | 1.5-2.5 | 110 |

| 110KW-3 | 21-36 | 2.5-3.5 | 110 |

| 110KW-4 | 20-30 | 3-4 | 110 |

| 200KW-2 | 50-80 | 1.5-2.5 | 200 |

| 200KW-3 | 50-78 | 2-3 | 200 |

| 200KW-4 | 40-60 | 3-4 | 200 |

| 250KW-5 | 50-70 | 2-5 | 250 |

| 250KW-7 | 30-65 | 5-7 | 250 |

| 250KW-8 | 40-60 | 7-10 | 250 |

| 355KW-2 | 70-120 | 1.5-2.5 | 355 |

| 355KW-3 | 65-110 | 2.5-3.5 | 355 |

| 400KW-2 | 125-160 | 1.5-2.5 | 400 |

| 400KW-3 | 90-120 | 2.5-3.5 | 400 |